It is estimated that a large percentage of the planet’s fresh water is used by different types of industries to manufacture products and by-products. Industries are therefore a large consumer of water, and reusing every drop of water brings industries closer to becoming increasingly sustainable, which, in addition to being a necessity, is beginning to be a requirement of end users.

In addition to to reduce the environmental impactreuse of industrial water, generates large economic savings for companiesThe main advantages of this approach are the reduction of demand, the pressure on the water supply, the elimination of the need to transport water and, therefore, the reduction of operating costs, making an industry a more efficient and profitable one. more cost-effective and efficient.

By reducing feed water consumption, chemical consumption is reduced to maintain the desired concentration.

– Lower pollutant load and flow in the influent of the wastewater treatment plant (WWTP), thus improving system performance and facilitating the implementation of water reclamation systems.

– Possibility of increasing production with the same WWTPI

– Lower cost of the landfill control fee

– Potential penalties for non-compliance of discharges reduced

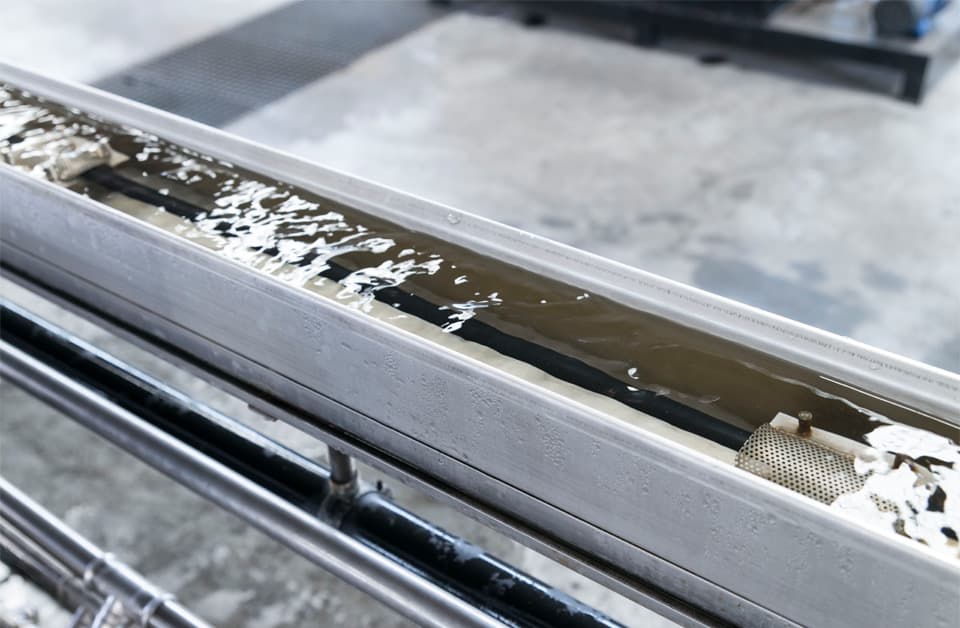

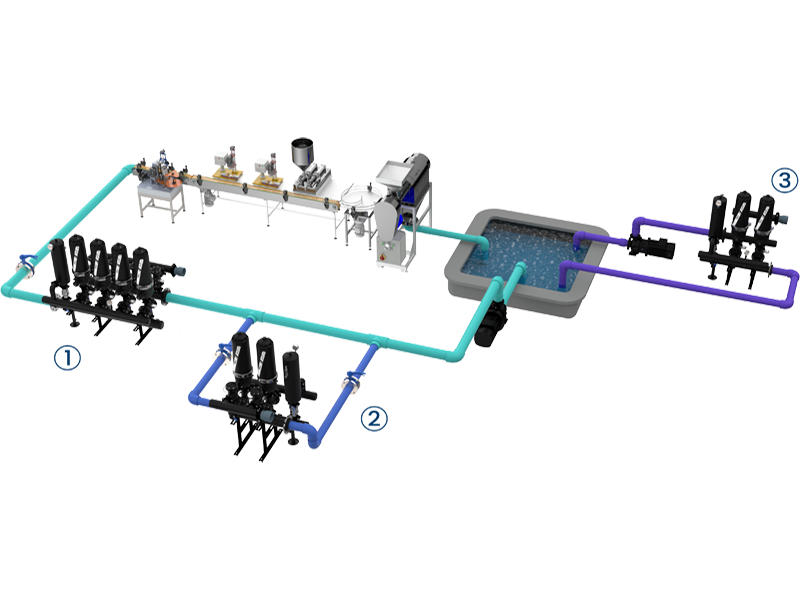

Filtration of 100 % of the circulating flow.

To remove coarse particles that may clog sensitive components or narrow passage sections, such as nozzles or measuring and control equipment.

Filtration of 5-20 % of the circulating flow.

To eliminate particles entering the system in installations where it is not desired to hydraulically interfere with the recirculation circuit.

Recirculation filtration equivalent to the total system volume every 4-6 hours.

For cleaning the buffer tank, in installations where the recirculation circuit is inaccessible or where hydraulic interference is not desired.