Cooling systems are present in various sectors such as municipal, industrial, residential and data processing centers (DPC), to dissipate the heat generated during their productive activity and ensure the optimum process temperature.

Although for many sectors, refrigeration systems are auxiliary installations, poor management of them can lead to large economic losses. It is necessary to achieve optimum operating conditions that guarantee a long service life of the installation.

These systems must manage large volumes of water and/or air, exposed to the ingress of particles that deposit and accumulate on the various heat transfer surfaces of the circuit. reducing plant performance, increasing the process water delivery temperature and resulting in productivity losses and increased costs.

Professionals know that, as water is continuously recirculated, its quality worsens due to the increase in the amount of suspended solids; however, most of the problems generated and associated with the proliferation of solids are rarely detected in time.

The continuous deterioration of water quality, due to the increase in the amount of solids inside the system, intensifies the phenomena of precipitation and sedimentation, favoring the accumulation of mineral and organic deposits on the heat transfer surface and in areas of low flow velocity.

This decreases the heat transfer rate of the tower, reduces the flow rate through the heat exchange surfaces, generating a higher incidence of corrosion and fouling phenomena and increasing the water discharge temperature and the direct and indirect operating costs of the tower.

Lower energy consumption

No deposits of solids, precipitates and biofilm on pipes and heat exchange surfaces to improve the heat transfer coefficient, optimizing the performance and energy efficiency of the cooling system.

An accumulation of particles in the system increases the thermal gradient between the cold source and the hot source, increasing the energy consumption of the pumping and ventilation equipment.

Increased cycles of concentration

Higher water quality increases the cycles of concentration, reducing the number of flushes needed to maintain the salt concentration in the system and avoid precipitates.

An increase in the cycles of concentration allows:

– Lower amount of water input.

– Reduced environmental impact by reducing the purge volume.

– No additional water consumption for backwashing the filtering equipment (backwash water volume < purge water volume).

– Lower chemical consumption due to increased water recirculation in the circuit.

Increased occupational safety of people

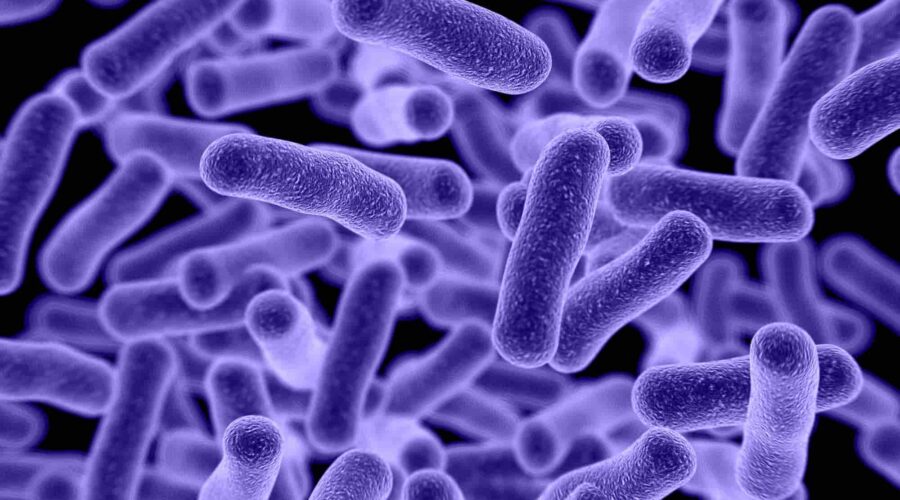

A higher quality of cooling water significantly reduces the risk of pathogen development, mainly Legionella, as particles in a cooling system can cause.

– INCRUSTATIONS; decrease cooling efficiency by increasing the temperature of the water in the circuit, which serves as a breeding ground for biological growths.

– SEDIMENTS; source of food and nesting of all types of germs.

– OBTURATIONS; facilitate water stagnation, favoring biofilm growth.

– Reduced operating costs

Reduced risk of clogging of diffuser nozzles in cooling towers, or plates/tubes in heat exchangers, avoiding unscheduled system shutdowns.

– Increased productivity

Increased efficiency of heat exchange equipment with less downtime for system cleaning and maintenance.

– Longer service life of the installation

Higher water quality reduces the working pressure of the system, minimizing the risk of breakage and deterioration of equipment and components.

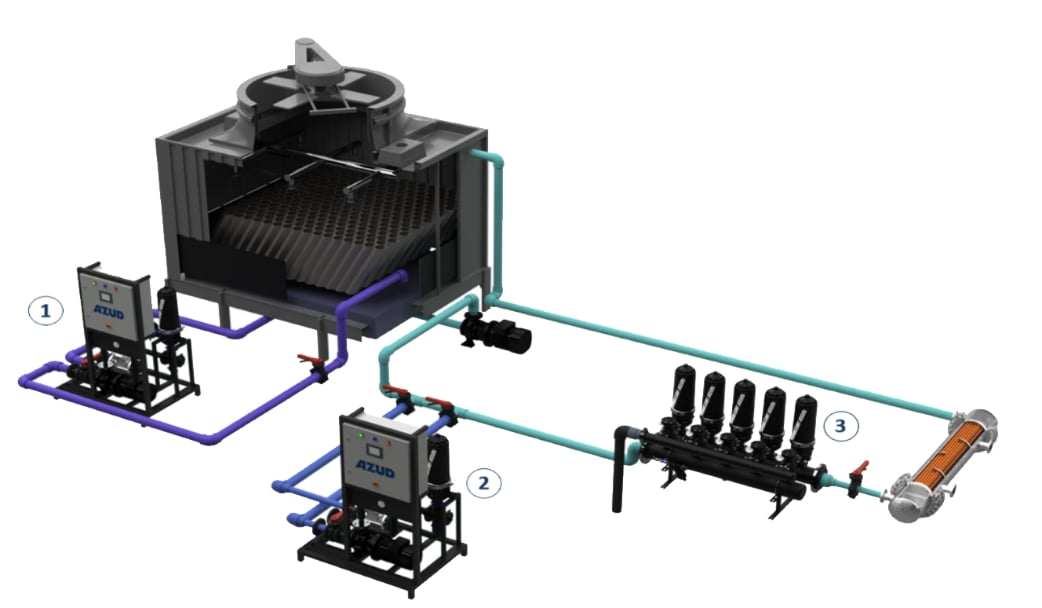

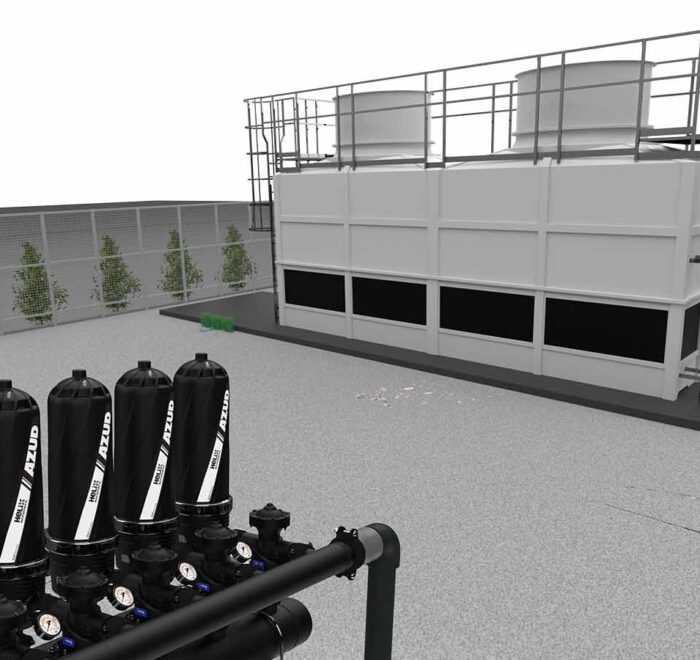

We offer different alternatives to protect cooling systems that can be combined for greater protection.